Textile & Dye-Sublimation Printers-

GUV Printers-

Old model-

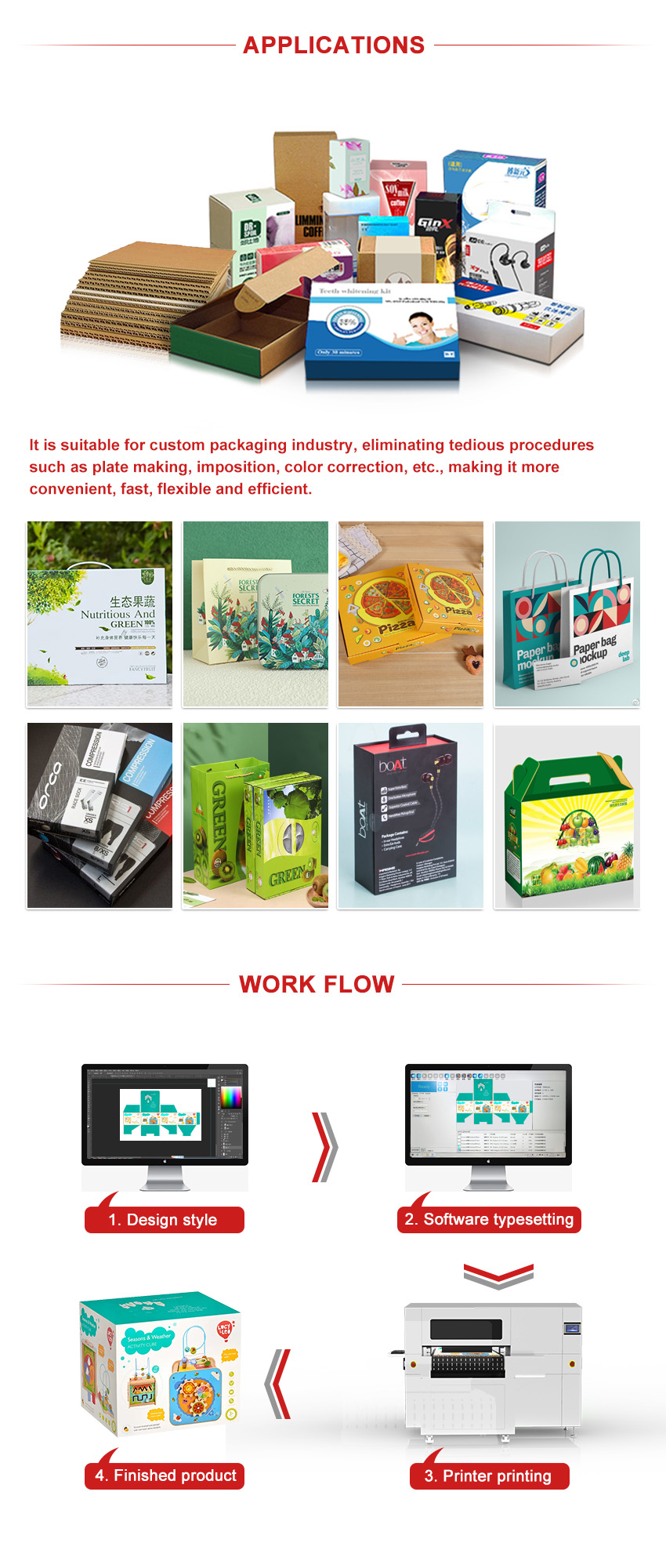

1. Convenient and fast:

It eliminates cumbersome procedures such as plate making, imposition, and color correction, and has absolute advantages in small and medium batch printing and urgent documents. All electronic patterns generated by typesetting, design software and office application software can be directly output.

2. Low carbon and environmental protection:

The traditional printing machine needs to be cleaned when changing varieties, which will generate a lot of sewage and pollute the environment; the ONE PASS high-speed plateless printing machine adopts four-primary-color inkjet printing technology without washing the machine.

3. Save labor:

The traditional printing process requires high printing technology for workers, a lot of labor, cumbersome adjustment process, time-consuming and labor-consuming, and low production efficiency;

Runnos ONE PASS high-speed plateless printing machine adopts computer graphics, computer color adjustment, computer preservation, printing on demand, saving time and effort, and high production efficiency.

4. Flexible and efficient:

Fully digital printing can provide more flexible printing methods, that is, printing and printing while printing, and printing while printing, realizing zero inventory in the true sense. This flexible and fast printing method enhances the customer's advantage in a competitive environment where every second counts.

1. Adopt high-precision transmission belt, high precision, excellent wear resistance, and stable transmission;

2. Servo motor + planetary deceleration drive, with Omron encoder, stable and fast conveying step;

3. Lifting cleaning mechanism, whole-stage scraping, better cleaning and moisturizing effect;

4. Electric lifting trolley, the lifting height is 0~20mm;

5. Smart touch screen + built-in display control, the operation is more convenient and intelligent.

6. The whole machine adopts steel pipe welded frame structure, the machine has high precision and good stability.

7. The ink cart printing area adopts a closed appearance to better protect the ink cart printing environment.

8. The overall appearance is simple and atmospheric.

| Xenonjet | ||

| Models | S800-packjet | |

| Print Head | epson i3200 | |

| Number of print heads | Maximum support: 16 | |

| Media | Width | 1920 mm (75.5 Inch) |

| Thickness | Maximum 20mm | |

| feed size | 800mm | |

| Printing Width | 540mm | |

| Bearing weight | Maximum 200KG | |

| Media application |

carton, paper bag, paper cup, cardboard, etc. | |

| Material file | TIFF BMP PDF EPS JPEG | |

| Printing accuracy | 300dpi/600dpi/900dpi/1200dpi | |

| Speed Color White Color |

30m~60m/min | |

| Inks | Types | Water Base |

| Ink Capacity | 3.5L (± 100 ml) | |

| Colors | KCMY+LC LM+W+V(Varnish) | |

| Printing platform | Integrated Tri-Heating System, Crawler platform without pressure roller design |

|

| Ink curing unit | UV LED | |

| Cleaning system | Positive pressure cleaning Separate ink pressure switch for each color | |

| Interface | High Speed USB-3.0/ Lan port | |

| Power supply | AC 110/220 V ± 10%, 50/60 Hz | |

| Printer Dimensions | Machine(L*W*H): 2460*2100*1580mm | |

| Package(L*W*H): 2280*2300*1780mm | ||

| RIP software | MT/PP/ONYX | |

| Weight (with stand) | Without table unit: 480 lb. (218 kg) | |

| Environmental | Temperature: 59° to 95°F (15° to 35°C) Humidity: 20% to 80% |

|

| PrintLinks System Requirements | |

| Operating system | Windows® 7/10 (64-bit) |

| CPU | Intel® Core™ 8, 4.0 GHz or faster recommended |

| RAM | 8 GB or more recommended |

| Video card and monitor | A resolution of 1,280 x 1,024 or more recommended |

| Free hard-disk space | 80 GB or more recommended |

| Hard-disk file system | NTFS format |

| Optical drive | DVD-ROM drive |

| Other requirements | Ethernet or USB port |

| Internet connection and web browser to software Registration | |